The design for wheelchair lift in the “L” Shaped House is the result of a carefully considered engineering effort. The first phase of this effort was an extensive search for a commercially available lift. I think it is almost always better to buy than build when you are looking for an item like this. The commercial builders (presumably) have the advantage of having gone through many design iterations and their products generally represent the culmination of this process. We found many examples of lift assemblies available in the marketplace. Ranging from manually actuated portable lifts all the way to elaborate built-in elevators. Unfortunately none of the commercial lifts we found would fit in the space we have available. The collage below shows some of the lifts we considered in the search. The Liftboy lifting platform from Powerlift (upper left) comes as close to meeting our requirements as any of them…but in the end all are either too big or don’t lift high enough.

The two lifts in the image below highlight the difficulty we faced while searching for a commercial lift to fit in the space available at the end of the stairs in the garage. Lifts generally fell into two categories; they were too wide or too long. It is also surprising how expensive these sorts of lifts are (nearly $6,000 for the blue one).

While searching we came across a few examples of homemade lifts. A Canadian gentleman built the lift shown below (I can’t find his link again). The very clever cantilevered design addresses many of the space considerations we face in our home. It is especially interesting because the platform could be lifted quite high without requiring a large footprint. We spent some time playing around with this compelling configuration. His implementation is kind of crude…he does not use any bearings in the vertical slide. The sketch shows some possible improvements to the slide assembly but this design (compelling as it is) has a few disadvantages related actuating and controlling the lifting platform. That is…the overhead structure supporting the pulleys and cables gets tall and implementing a safe and simple control would be a little challenging (his is just a momentary switch). Furthermore I’ve found it challenging to get motor driven cable systems to operate smoothly. We considered the possibility of using a garage door actuator but could not find a small enough version anywhere.

Given our reservations related to controls for our lifting mechanism we expanded our search to include some other kinds of lifts. A number manufactures build lift assemblies that incorporate linear actuators in their designs. The linear actuators used generally include all sorts of nice control features like built in limit switches and “soft start” motors. Examples of these include the many different versions of lifts used to transport electric scooters for the disabled. Unfortunately no one makes a lift rated for wheelchairs that lifts 48”. The image below shows two examples of these sorts of lifts. The Burr Handi-Lift is an interesting example that lifts to higher heights but they specifically exclude wheelchairs.

Our search turned up a fascinating possibility in the form of a personal watercraft dock lift. Several manufactures produce these lifts with both manual and electric actuators and integrated control systems. As interesting as this seems…this kind of lift has some disadvantages. The cantilevered platform has to be pretty robust (think tall) to accommodate the load and therefore ends up sitting something like 6” off the floor in the lowered position.

The simplicity and (relative) low cost of the mid-rise lift I purchased from Greg Smith Equipment for the third stall in the garage compelled us to look closely at this design. These kinds of hydraulically actuated scissors lifts are very common in industrial applications. The Atlas TD6MR has more than 48” of stroke and is capable lifting 6,000 pounds. Furthermore the hydraulic control system is quiet, smooth, safe, and runs off a single 120 volt outlet.

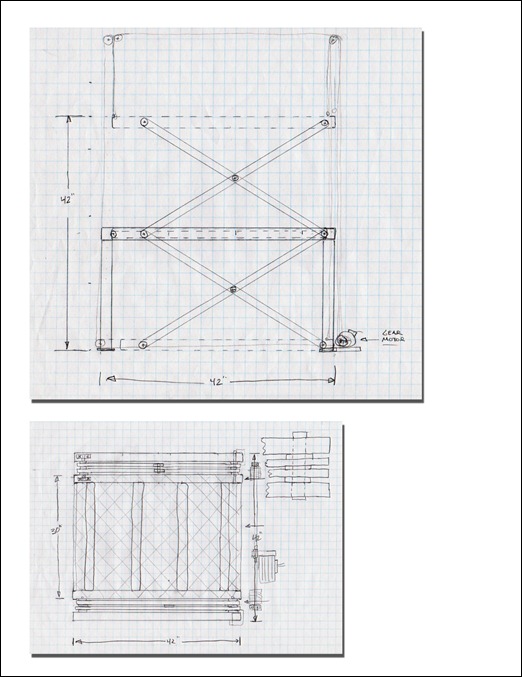

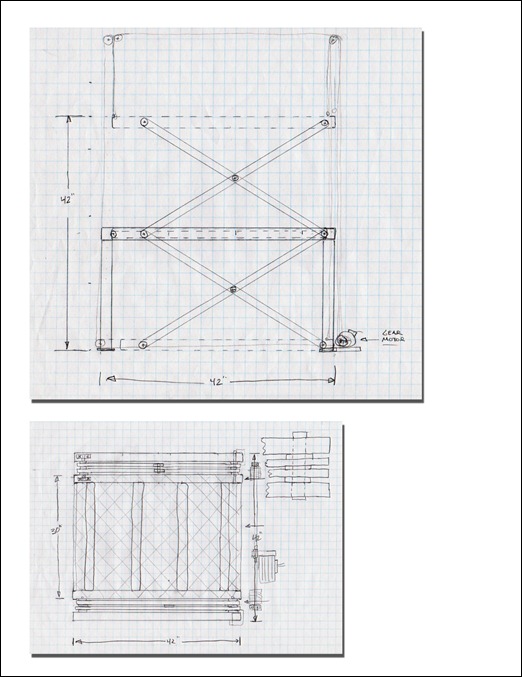

A scaled drawing of a scissors lifting mechanism tailored to the space available clearly shows that a single set of lifting arms results in a mechanism that would be unstable in the fully raised position. I produced the sketch below to inform Dan Oss and Byron Knapp (PICo’s engineering team) as we asked some questions about the structural elements of the lift mechanism. I was specifically interested in understanding the effects of lengthening one of the lifting bars.

Dan quickly produced the CAD model shown here that shows how this structure works. The unequal length arms cause the platform to rotate slightly as the lift is raised. Carefully placing pivot points in the structure results in a platform that is tilted slightly forward at the bottom and slightly backward at the top of the travel. Even with this one extended lifting arm the structure looks a little unstable at the top of its travel.

Working with this model quickly exposed the advantages of a “compound” scissors arrangement. In this configuration two sets of connected lifting bars push the platform to the same height while maintaining a comfortable (stable) spread even at the top of the travel. The lower sketch shows a possible motorized lifting configuration that allows the bars to clear one another as the platform is raised.

As Dan’s experiments with the structure continued another possibility emerged. This time pairs of lifting arms tied together at their centers rotate and slide along a connecting rod as the stage is raised. This arrangement is superior to the previous in that the lifting bars are really quite short in relation to the stroke of the lift. It also provides for an uncluttered area between the bars for a possible actuator.

The next sketch shows the real breakthrough in this process. Dan quickly discovered that combining a single full length lifting bar with two half length bars allowed for a structure that not only has fewer parts but also provided more flexibility for actuators. The sketches below show the mechanism as it quickly evolved. The first shows it with a full side panel supporting the arms while we see the greatly simplified support structure in the second.

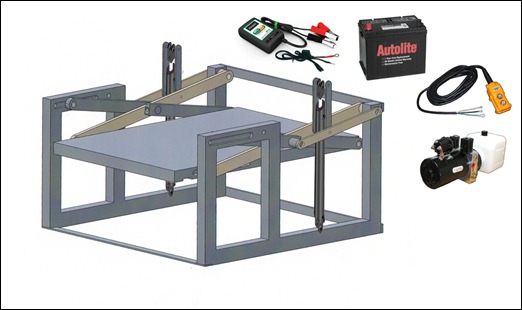

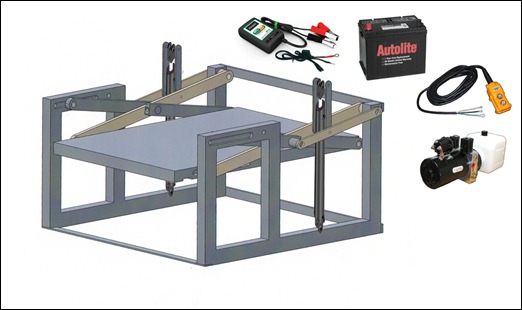

The 3D CAD model below shows the lift assembly in its final form (the back side lifting mechanism is removed for clarity). Here we see the lifting platform fully raised with the hydraulic cylinder in place in the structure. The hydraulic actuator is positioned slightly off center on the lifting bar so that a cylinder with 14” of stroke produces 42” of platform motion. The ends of the lifting bars are guided in linear slides and the cylinder is tucked snugly in-between. All of the elements in the structure are sized to provide a 1000 lb. lift rating which should easily accommodate our expected maximum 400 lb. requirement.

We plan to use a hydraulic control system from Dalton Hydraulics. The MTE Hydraulic Pumping Station (250-730) is a D.C. powered system that we will connect to a deep-cycle battery with a “maintainer” charging system. The D.C. system will allow us to use the lift in the event we lose electrical power in the house. Multiple wired remotes will allow us to have push button control both on the platform and at the top and bottom of the lift.